Tenders Description & Specification for Four Point Bend Test for UTM

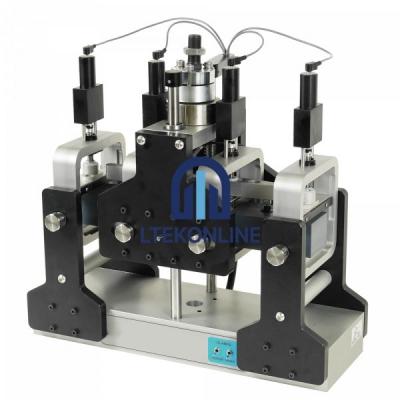

Four Point Bend Test for UTM

To perform Four Point Bend test

Main Features:

Designed to subject an asphalt specimen to four point bending with backlash free rotation and horizontal translation of all load and reaction points

Sinusoidal or haversine controlled strain or controlled stress loading

Controlled force, motorized specimen clamping

Innovative “floating straight-edge” on specimen transducer displacement measurement eliminates errors

Optional fixed point strain measurement referring from outer pivots

Loading frequency up to 60 Hz

Cost effective solution for high volume testing

Vertical clamping of the specimen is achieved by servo-motor driven ball screws, which are operated continuously during the test to take up the compliance of the specimen at the clamping surfaces

Specimen laterally positioned by hand using etched lines as visual guide for two specimen sizes, nominally 50 and 63.5 mm in width

Non-linear regression data fitting ensures reliable determination of phase and modulus

Can be used with existing UTM systems

Extra Large Four Point Bend Jig

Innovative floating on-specimen transducer eliminates errors caused by frame compliance

Specimen rollers with pneumatic lift and lowering for easy loading of specimen

Automated self-aligning specimen yokes for easy specimen insertion

Specimen roller with pneumatic lift and lowering provide the user with easy test set-up across a range of extra-large specimen sizes

Backlash free rotation and translation on all load and reaction points

Controlled force and motorized specimen clamping

Vertical clamping of the specimen is achieved by servo-motor driven ball screws, which are operated continuously during the test to take up the compliance of the specimen at the clamping surfaces.

Technical Specifications:

Load capacity: up to 10 kN dynamic

Loading frequency: up to 60 Hz

Specimen size (h x w x l): 70 (max) x 80 (max) x 380 mm

Dimensions (h x w x d): 455 x 460 x 230 mm

Yoke alignment tool for specimen: 50 x 50 x 355.5 mm (h x w x outer span centers), 70 x 70 x 420 mm (h x w x outer span centers)

Weight: 35 kg

Extra Large Four Point Bend Jig

Load capacity: up to 25 kN dynamic

Specimen size (l x h x w): 790 (min) x 100-160 x up to 200 mm

Dimensions (h x d x w): 790 x 435 x 890 mm

Weight: 210 kg

Air supply: clean, dry air at 700 kPa.

Yoke alignment tool for specimens: 740 mm (outer span centers), 247 mm (inner span centers).

Ltekonline are the manufacturers of Four Point Bend Test for UTM used to demonstrate engineering principles in Engineering Colleges, Engineering Schools and Asphalt Mix Testing for Engineering Teaching Lab in Universities