Tenders Description & Specification for Liquid Extraction Unit

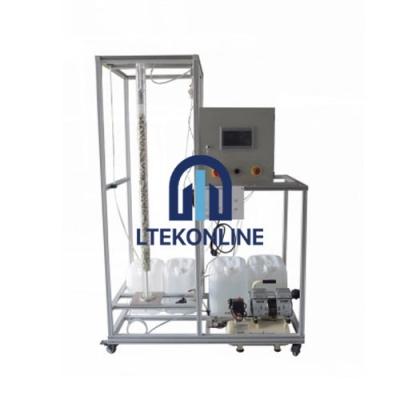

Liquid Extraction Unit

Designed to handle Kerosene with a thermostat to limit maximum operating temperature for safe operation

Touch panel for control / calibration of pumps and display of measurements

Operation with the organic or the aqueous phase as the continuous phase inside the column

Recommended system uses water to separate Acetic acid from Kerosene

Sensors measure the temperature and conductivity of the aqueous phase before and after the extraction process allowing the concentration of acid to be determined and the extraction efficiency to be calculated

A single valve sets the organic phase or the aqueous phase as the continuous phase as required for a particular exercise

Simple adjustment of lower phase boundary to compensate for variation in specific gravity of the organic phase

Location of the phase boundary is predetermined by the density difference between the phases with no sensors or controls involved

Pneumatic diaphragm pump used to minimize risk of ignition of the organic phase

Includes PC software allowing data logging of measurements and calculation of acid concentration in the aqueous phase

No solvent recovery system is necessary using the recommended Kerosene system, (the used Kerosene can be disposed of, or else reused by performing a simple assay and topping up with acetic acid).

Technical Details:

Aqueous phase circulation system with a approx. 25l feed tank, approx. 25l return tank and variable speed pump. Pump is calibrated and gives flows of approx. 50-250ml/min

Column packed with preferably 15mm glass Rashig rings

Column length approx. 1.6m (1.2m working length), 50mm diameter, made from glass

Fine adjustment of the lower phase interface to compensate for variation in specific gravity of the Kerosene

Instrumentation measures the inlet and outlet concentrations in the aqueous phase when using the recommended acid

Touch panel for control / calibration of pumps and display of measurements

A single valve sets either the organic phase or the aqueous phase as the continuous phase

Organic phase circulation system with an 18l feed tank, 18l return tank and variable speed air operated pump. Pump is calibrated and gives flows of approx. 50-250ml/min

Includes valves for taking samples of both phases for analysis.

Ltekonline are the manufacturers of Liquid Extraction Unit used to demonstrate engineering principles in Engineering Colleges, Engineering Schools and Heat Transfer Lab Equipments for Engineering Teaching Lab in Universities