Tenders Description & Specification for Research Ductilometer for Force Ductility Test

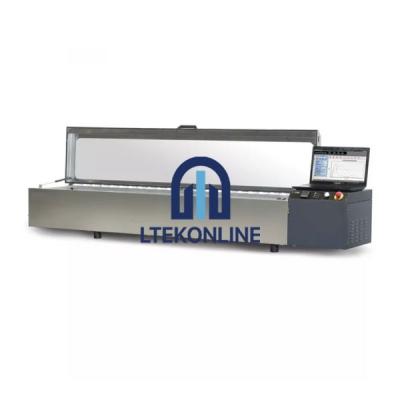

Research Ductilometer for Force Ductility Test

The ductility test is performed for determining the ductility of bituminous materials by measuring the elongation before breaking when two ends of briquette specimens are pulled apart at a specified speed and temperature.

Water bath

Insulated stainless steel water bath with a heating system located over the entire base surface and a stainless steel cooling coil (for connection to water mains or chiller) distributed over the three side walls assuring temperature uniformity without water turbulence inside the bath. All parts in contact with water are made of stainless steel.

Carriage displacement

Double-screw rods and mobile carriage enable test speeds from 3 to 200 mm/min. The system also permits the fast return of the carriage at the end of the test (500 mm/min) to reduce dead time and increase productivity. The carriage return is automatic, manual intervention is not required.

Temperature control

The thermoregulation system is based on control of the heater (which increases the temperature of the bath) and the control of the flow rate of the cooling coil by an electro-valve. This important feature assures control of the temperature within strict limits and permits the use of suitable standard water chillers.

A closed-loop PID system assures constant temperature from -10 to +60°C, with a water chiller (see accessories)

Stainless steel cooling coil

Plate-type base heaters give better temperature uniformity

Load and elongation measurement

Automatic measurement of the elongation by an encoder. Includes a system for measuring forces up to 2000 N (4 x 500 N) with load cells (see accessories).

Testing software:

Test control by PC: Start-Stop-Carriage return

Specimen failure recognition

Real-time display of load/elongation graph with advanced visualization options (single or multi-graph)

Selection of test parameters (speed, temperature etc.) by PC. The test temperature, however, can be set in advance using the control panel of the machine.

Function for multiple test data comparison

Storage of test data

Data acquisition and processing conforming to Standards

Machine control

Water cooling

This model is proposed without a chiller for use with a suitable cooling system that could be available in the laboratory. It is important, however, that this unit is capable of delivering a flow rate of 6 litres/min, 1 bar, at the minimum temperature of 2°C.

Main Features:

4 tension line (briquette capacity) x 1500 mm

Easy and free access to the large testing space

Stainless steel insulated water bath

Includes a system for measuring forces up to 4x500 N with load cells

Temperature range from -10 to 60°C

Double drive screw rod

Closed-loop PID temperature control system

Elongation measurement by optical system

Real-time load and displacement graphics via PC

Exclusive in-built thermoregulation system compensating the control, optimized by the connection to chiller (optional)

High carriage return speed of 500 mm/min for greater productivity

Adjustable speed range from 1 to 200 mm

PC-controlled using dedicated software

Includes a system for measuring forces up to 2000 N (4 x 500 N)

Extensive use of stainless steel for frame, cover and tank.

Ltekonline are the manufacturers of Research Ductilometer for Force Ductility Test used to demonstrate engineering principles in Engineering Colleges, Engineering Schools and Asphalt Binder Testing Equipment for Engineering Teaching Lab in Universities